Have you ever wondered what goes into the creation of the delicious cheese varieties we enjoy?

Cheese making is a fascinating process that relies on a variety of animal milks to produce an array of flavors and textures. Did you know that apart from the traditional cow milk, there are other animal milks that play a crucial role in the diverse world of cheese?

In this article, we will delve into the world of cheese making and explore the surprising range of animals involved. From the tangy goat milk to the creamy sheep milk and even the exotic camel and yak milk, each type of milk brings its own unique characteristics to the cheese making process.

So, are you ready to discover the hidden secrets behind your favorite cheeses and unveil the incredible variety of animal milks used for cheese making? Let’s dive in!

Introduction to Cheese Making and Animal Milks

In the fascinating world of cheese making, the process of transforming milk into a delectable and diverse range of cheeses is a true art form. Let’s take a closer look at the cheese making process and the crucial role that animal milks, especially ruminants’ milk, play in producing these beloved dairy delights.

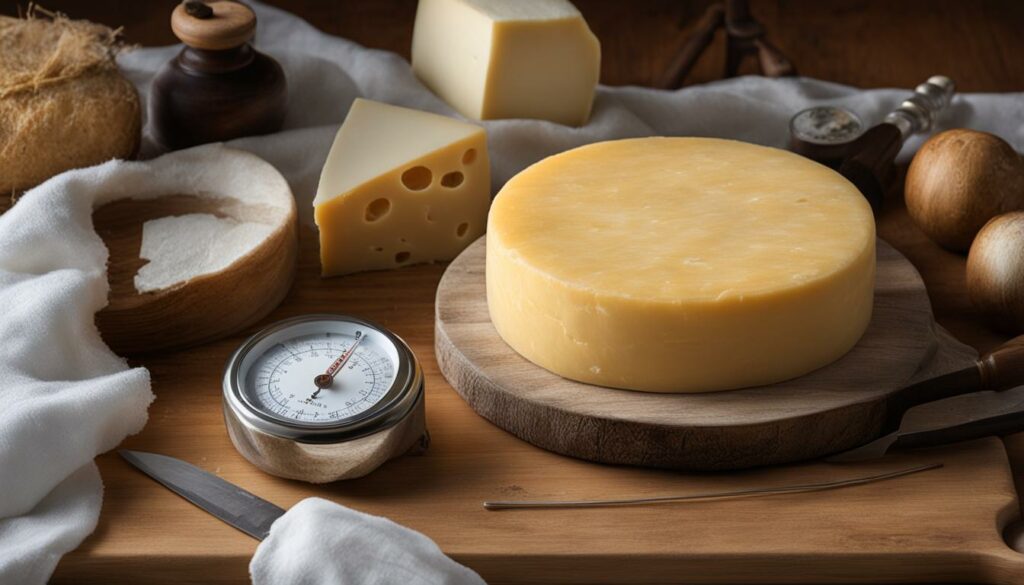

Understanding the Cheese Making Process

The cheese making process involves several key steps that turn milk into cheese. Firstly, the milk is heated and then acidified by the addition of bacteria or other cultures. This acidification helps to lower the pH level of the milk, which is essential for coagulating the proteins and forming the curds. Once coagulation occurs, the curds are cut, stirred, and heated to release the whey, which is then drained. The remaining curds are salted and molded into the desired shape before being aged to develop their distinct flavors and textures.

The cheese making process is a delicate balance of timing, temperature, and technique, as each stage contributes to the final product’s unique characteristics.

Role of Ruminants’ Milk in Cheese Production

Ruminants’ milk, such as cow, goat, and sheep milk, holds a special place in cheese production due to its composition, which lends itself well to the cheese making process. These milks have a higher concentration of proteins, particularly casein, which is crucial for curd formation. The curd is formed when the proteins in the milk coagulate, creating a solid mass that can be transformed into cheese.

Moreover, ruminants’ milk contains substances that contribute to the development of complex flavors during the aging process. These substances include enzymes, fatty acids, and lipids, which break down and release various aromatic compounds as the cheese matures. This aging process allows the cheese to develop its unique flavor profile, ranging from mild and creamy to sharp and tangy.

Ruminants’ milk sets the foundation for creating a wide variety of cheeses, each with its own distinct taste and texture.

| Cheese Making Process Steps | Role in Cheese Production |

|---|---|

| Heating and acidifying the milk | Prepares the milk for coagulation and curd formation |

| Coagulating and cutting the curds | Forms the solid mass of curds that will become cheese |

| Draining and salting the curds | Removes excess whey and adds flavor to the curds |

| Molding and shaping the cheese | Gives the cheese its desired shape and texture |

| Aging the cheese | Allows the cheese to develop its unique flavors and textures |

Cow Milk: The Staple of Dairy Production

Cow milk is the foundation of dairy production and a key ingredient in cheese making. It is the most widely used milk in the industry, thanks to its abundance and versatility. Cow milk provides a rich and creamy base for a wide range of dairy products, from milk and butter to yogurt and, of course, cheese.

Composition and Characteristics of Cow Milk

Cow milk is packed with essential nutrients that contribute to its unique composition and characteristics. It is rich in proteins, such as casein and whey, which are vital for curd formation in cheese making. The fat content in cow milk gives it a creamy texture and contributes to the flavor of the resulting cheese. Additionally, the lactose present in cow milk provides a natural sweet taste, adding complexity to various cheese varieties.

“The composition of cow milk sets the stage for the cheese making process, allowing for the development of distinct flavors and textures.”

Table:

| Component | Percentage in Cow Milk |

|---|---|

| Fat | 3-4% |

| Protein | 3-4% |

| Lactose | 4-5% |

The Versatility of Cow Milk in Cheesemaking

One of the remarkable qualities of cow milk is its versatility in the cheese making process. It can be used to produce a wide range of cheese varieties, each with its own unique flavor profile and texture. The fat content in cow milk allows for the creation of creamy and buttery cheeses, while the protein composition contributes to the formation of stretchy and melty cheeses, like mozzarella.

From mild cheddars to tangy goudas and velvety bries, cow milk can be transformed into an array of cheeses that cater to different palates and culinary preferences. Its versatility makes it an indispensable ingredient in the cheese making industry, enabling cheese makers to experiment and create new and exciting flavors.

Cow milk’s ability to adapt to various cheese making techniques and recipes has made it a staple choice for both commercial and artisanal cheese production. Its availability and consistency have also contributed to its popularity in the industry, ensuring a steady supply for cheese makers worldwide.

Goat Milk: A Tangy Alternative for Artisanal Cheese

When it comes to artisanal cheese production, goat milk has become an increasingly popular choice among cheese makers and cheese enthusiasts alike. The unique qualities of goat milk contribute to the tangy and distinct flavors found in many goat milk cheeses. In this section, we will delve into the nutritional profile and benefits of goat milk, as well as explore how the diet of goats influences the flavor of their milk.

Nutritional Profile and Benefits of Goat Milk

Goat milk boasts a rich nutritional profile that sets it apart from other types of milk. While the exact composition may vary depending on factors such as breed and diet, goat milk generally contains higher levels of protein, calcium, and certain vitamins compared to cow milk.

One of the key benefits of goat milk is its unique protein structure. The protein in goat milk forms a softer curd during the cheese making process, resulting in a smoother and creamier texture in the final product. Additionally, goat milk has a lower lactose content, which makes it a viable option for individuals with lactose intolerance.

Influence of Diet on Goat Milk Flavor

Just like humans, the diet of goats can greatly impact the flavor of their milk. The plants and herbs that goats graze on can introduce a range of flavors and aromas into their milk, which are then translated into the cheese. This is why goat milk cheeses often exhibit a distinctive tanginess and earthy undertones.

Cheese makers who specialize in artisanal goat milk cheeses carefully consider the diet of their goats to control and enhance the flavor profile of their cheese. From wild herbs to fresh grasses, the diverse diet of goats contributes to the complexity and depth of flavor found in these cheeses.

Sheep Milk: Creamy and Nutty Flavors

Sheep milk is highly valued in the world of cheese making for its rich and creamy texture, as well as its distinct nutty flavor. This unique milk brings a luxurious and indulgent character to a variety of sheep milk cheeses.

The Richness of Sheep’s Milk for Cheese Making

Sheep’s milk is naturally high in fat and protein, which contributes to the velvety smoothness and richness of sheep milk cheeses. The higher fat content gives these cheeses a luscious mouthfeel, while the elevated protein content helps create a firm and well-structured texture.

Moreover, the composition of sheep’s milk allows for a unique aging process, enabling the development of complex flavors and aromas. The cheese matures beautifully, intensifying its distinct creamy and nutty characteristics over time.

Celebrated Sheep Milk Cheeses

Sheep milk cheeses have a long-standing tradition and are cherished in many culinary traditions around the globe. Some of the most celebrated sheep milk cheeses include:

Pecorino Romano: This Italian cheese hails from the regions of Lazio and Sardinia. It boasts a salty and sharp flavor profile, accompanied by a rich and crumbly texture. Pecorino Romano is often used as a grating cheese in pasta dishes and adds depth to various culinary creations.

Roquefort: Originating in France, Roquefort is a pungent and tangy blue cheese made from sheep’s milk. Its creamy and crumbly texture is interlaced with distinctive blue veins. Roquefort’s rich and complex flavor profile enhances gourmet dishes and cheese platters, providing a delightful sensory experience.

These renowned sheep milk cheeses exemplify the sublime combination of creamy and nutty flavors that can be achieved through the use of sheep’s milk in cheese making.

Buffalo Milk: Mozzarella’s Main Ingredient

Buffalo milk plays a crucial role in the creation of one of the most beloved cheeses in the world – mozzarella. With its stretchy and melt-in-your-mouth texture, mozzarella owes its unique characteristics to the use of buffalo milk.

What sets buffalo milk apart from cow milk, the more commonly used milk in cheese making, are its higher levels of fat and protein. These qualities contribute to the rich and creamy flavor that buffalo milk brings to mozzarella cheese.

Beyond mozzarella, buffalo milk is also used to create a variety of texturally rich cheeses. The higher fat content of buffalo milk lends itself well to producing cheeses that are creamy, indulgent, and full of flavor. Cheese enthusiasts often seek out these buffalo milk cheeses for their unique taste experiences.

Diving Into Lesser-Known Animal Milks Used for Cheese

While cow, goat, and sheep milk are the most common choices for cheese making, there are also lesser-known animal milks that yield unique cheeses. In this section, we will explore exotic milk sources such as camel and yak milk, discussing their distinctive qualities and the challenges involved in working with these uncommon animal milks. We will also highlight the premium nature of cheeses made from these exotic milks.

Exploring Exotic Milk Sources: From Camel to Yak

When it comes to creating truly exceptional cheeses, cheesemakers sometimes turn to unconventional sources of milk. Camel milk, for example, offers a rich and creamy base that lends a unique flavor profile to cheeses. Yak milk, on the other hand, is known for its high protein and butterfat content, resulting in cheeses with a luxurious texture and complex taste.

The Challenges and Premium Nature of Uncommon Animal Milks

Working with uncommon animal milks presents its own set of challenges for cheesemakers. These milks often have different compositions and properties compared to traditional dairy milks, requiring adjustments in the cheese making process. Additionally, sourcing and obtaining these exotic milks can be more difficult and expensive, contributing to the premium nature of the cheeses made from them.

Despite the challenges, the allure of creating cheeses from these exotic milk sources lies in the opportunity to offer cheese enthusiasts something truly extraordinary. These cheeses command attention and are often prized for their unique flavors, textures, and stories behind their production.

Cheese Making Efficiency Across Different Milk Types

In cheese making, the choice of milk type plays a crucial role in determining the efficiency of the process. Different milk types, such as cow, goat, sheep, buffalo, and exotic milks, possess unique coagulation properties and curd firmness, which directly impact the cheese production process.

To better understand the variations in cheese making efficiency, let’s compare these factors across different milk types:

Comparing Coagulation and Curd Firmness Across Species

Cow Milk: Cow milk is known for its relatively fast coagulation time and firm curd formation. The coagulation properties of cow milk make it suitable for a wide range of cheese varieties, including hard cheeses like cheddar.

Goat Milk: Goat milk tends to have a slower coagulation time compared to cow milk. Additionally, the curds formed from goat milk are typically softer and more delicate, resulting in cheeses with a creamier texture and tangy flavor.

Sheep Milk: Sheep milk has a high coagulation rate and produces a firm curd, making it ideal for creating hard and aged cheeses. The resulting cheeses from sheep milk are known for their rich and nutty flavors.

Buffalo Milk: Buffalo milk has unique coagulation properties that contribute to the characteristic stretchiness and melt-in-your-mouth texture of mozzarella cheese. It forms a softer curd compared to cow milk, which allows for the creation of softer and creamier cheeses.

Exotic Milks: Exotic milks like camel and yak milk have distinct coagulation properties that require specific techniques for optimal cheese production. These milks often have slower coagulation times and produce curds with varying firmness, resulting in cheeses with unique flavors and textures.

Optimizing Cheese Production for Specific Animal Milks

To achieve the desired flavor and texture in cheese, it is essential to optimize the production process for each specific animal milk. This involves understanding the unique coagulation properties and curd firmness of the chosen milk type and adjusting factors such as fermentation time, temperature, and acidification levels.

By optimizing cheese production techniques for specific animal milks, cheesemakers can ensure consistent quality and maximize the efficiency of the cheese making process. This attention to detail allows for the creation of a wide variety of flavorful and distinct cheeses that cater to different palates.

Rennet and Its Role in Milk Coagulation for Cheese Making

Rennet plays a crucial role in the milk coagulation process for cheese making. It is an essential ingredient that helps to transform liquid milk into solid curds, which are then used to produce various types of cheese.

During the cheese making process, rennet helps to coagulate the milk proteins, specifically the casein proteins. These proteins form a network of curds, trapping the fat and other solids, while the whey liquid is separated.

There are different types of rennet available, such as animal rennet, microbial rennet, and vegetable rennet. Animal rennet is extracted from the stomach lining of young ruminant animals, while microbial and vegetable rennet are produced through fermentation or extraction from plant sources.

The type of rennet used can have an impact on the flavor, texture, and characteristics of the final cheese product. It is important for cheese makers to choose the right type of rennet based on the desired outcomes they want to achieve.

Rennet is a crucial component of the cheese making process, enabling the transformation of milk into curds. Its role in milk coagulation is essential for creating the solid structure of cheese and achieving the desired flavors and textures that cheese lovers enjoy.

Choosing the Right Milk for Your Cheese: Factors to Consider

When it comes to cheese making, choosing the right milk is essential for achieving the desired quality and flavor. The type of milk used can have a significant impact on the final product, influencing its texture, taste, and overall cheese quality. In this section, we will explore the important factors to consider when selecting milk for cheese making and discuss the differences between raw and pasteurized milk, as well as whole milk and skim milk, to help you make the best choice for your cheese.

Impact of Milk Selection on Cheese Quality

The quality of cheese is closely tied to the quality of the milk used in its production. The composition of the milk, including its fat, protein, and lactose content, plays a crucial role in determining the texture, flavor, and overall characteristics of the cheese. Different milks have unique compositions, resulting in distinct cheese profiles. For example, cow milk, with its higher fat content, tends to produce creamier and richer cheeses, while goat milk imparts a tangy and slightly earthy flavor. By carefully selecting the milk, you can achieve the desired cheese quality that aligns with your preferences and culinary goals.

Raw vs Pasteurized, Whole vs Skim: Making the Best Choice

One important decision to make when choosing milk for cheese making is whether to use raw or pasteurized milk. Raw milk is milk that has not undergone any heat treatment, while pasteurized milk has been heated to kill harmful bacteria and extend its shelf life. Both types of milk have their own advantages and considerations. Raw milk is often favored by artisanal cheese makers for its potential to develop unique flavors and aromas due to the presence of natural microorganisms. However, it also carries a higher risk of foodborne illnesses. Pasteurized milk, on the other hand, offers a greater level of safety but may require additional cultures or starter bacteria to achieve the desired cheese characteristics.

The choice between whole milk and skim milk is another factor to consider. Whole milk contains a higher percentage of fat, which contributes to a creamier texture and richer flavor in the cheese. Skim milk, on the other hand, has a lower fat content and can result in a leaner and more delicate cheese. The decision between whole milk and skim milk depends on personal preference and the type of cheese you aim to produce. Some cheese varieties, such as creamy bries, may benefit from the richness of whole milk, while others, like lighter feta or fresh cheeses, may require the lighter touch of skim milk.

Ultimately, the choice of milk for cheese making is a personal one, influenced by your desired cheese characteristics, safety considerations, and taste preferences. By understanding the impact of milk selection on cheese quality and considering factors such as raw vs pasteurized and whole vs skim milk, you can make an informed decision that sets the foundation for creating delicious and high-quality cheeses.

Homogenization, Pasteurization, and Other Milk Processing Techniques

In the world of cheese making, milk processing techniques play a crucial role in determining the quality and characteristics of the final product. Two widely used techniques are homogenization and pasteurization, each serving a unique purpose in the cheese making process.

Homogenization: Homogenization is a process that breaks down the fat globules in milk, ensuring a consistent distribution throughout the liquid. This technique prevents the cream from rising to the top and creates a smoother texture in the final cheese. By enhancing the milk’s homogeneity, homogenization contributes to the desirable mouthfeel and appearance of certain cheese varieties.

Pasteurization: Pasteurization is a heat treatment process that eliminates harmful bacteria and pathogens from the milk without significantly altering its nutritional value. This technique involves heating the milk to a specific temperature and then rapidly cooling it. Pasteurization not only ensures food safety but also extends the shelf life of milk products. For cheese making, pasteurized milk provides a clean slate for the growth of beneficial bacteria and the development of desired flavors and textures during the aging process.

While homogenization and pasteurization are commonly used in milk processing for cheese making, there are other techniques that can also influence the final cheese product. These techniques include:

- Ultrafiltration: A process that separates components of milk based on size, resulting in a concentrated milk product with higher protein content.

- Microfiltration: The use of microfilters to remove bacteria and unwanted particles from milk, ensuring a cleaner and safer product for cheese making.

- Membrane filtration: A process that selectively removes or concentrates specific components from milk, allowing for the customization of milk composition for different cheese styles.

- Direct acidification: The addition of specific acids directly to milk to achieve the desired pH level for cheese making, bypassing the need for fermentation.

These milk processing techniques provide cheese makers with additional options to manipulate and optimize the cheese production process, leading to a wide variety of cheese flavors, textures, and styles.

As seen in the image above, homogenization and pasteurization are key milk processing techniques used in cheese making, each serving a unique purpose in achieving the desired cheese quality. By understanding and implementing these techniques effectively, cheese makers can create cheeses that cater to diverse palates and preferences.

Conclusion

The choice of milk in cheese making is of utmost importance, as it directly influences the flavors, textures, and overall quality of the final product. Throughout this article, we have explored the diverse range of animal milks used in cheese production, including cow, goat, sheep, buffalo, camel, and yak milk. Each milk brings its own unique qualities to the cheese making process, resulting in a wide variety of cheese flavors that cater to different palates.

By carefully selecting the type of milk, cheese makers can achieve specific characteristics desired for their cheeses. Cow milk, for example, is known for its versatility and is commonly used to produce a wide range of cheese varieties. Goat milk, on the other hand, offers a tangy alternative and is popular for artisanal cheese production. Sheep milk brings a creamy and nutty flavor profile to the table, while buffalo milk is renowned for its role in creating the beloved mozzarella cheese.

It’s also important to appreciate the diversity that animal milks bring to the world of cheese. Each milk type offers a unique taste experience, allowing cheese lovers to explore a wide range of flavors and textures. Whether you prefer the rich and creamy sheep milk cheeses or the distinctive tang of goat milk cheeses, the use of different animal milks adds depth and variety to the cheese selection available to consumers.

So, the next time you savor a delicious piece of cheese, take a moment to appreciate the careful milk selection and the expertise of cheese makers who have crafted it. The choice of milk plays a vital role in creating the wonderful world of cheese, and it is through this variety that we can truly indulge in the rich and diverse flavors that make cheese such a beloved culinary delight.

FAQ

What are the animal milks used for cheese making?

The animal milks used for cheese making include cow, goat, sheep, buffalo, camel, yak, as well as other exotic milks such as moose and reindeer milk.

How is cheese made from animal milk?

Cheese is made from animal milk through a process that involves curdling the milk using rennet or other coagulating enzymes, separating the curds from the whey, and then aging the curds to develop the desired flavors and textures.

What are the key steps in the cheese making process?

The key steps in the cheese making process include milk coagulation, curd cutting, whey draining, curd pressing, salting, and aging.

Why is ruminants’ milk suitable for cheese making?

Ruminants’ milk, such as cow, goat, and sheep milk, is suitable for cheese making due to its composition, which allows for effective curd formation and the development of complex flavors during the aging process.

What are the characteristics of cow milk for cheese making?

Cow milk, the most widely used milk in dairy production and cheese making, has a balanced composition of fat, protein, and lactose. It is versatile and can be used to create a wide range of cheese varieties.

What are the benefits of using goat milk for artisanal cheese production?

Goat milk is valued for its unique protein structure and lower lactose content compared to cow milk. It also has a tangy and distinct flavor, influenced by the diet of the goats, making it a popular choice for artisanal cheese production.

What makes sheep milk suitable for cheese making?

Sheep milk is valued for its rich and creamy texture, high fat and protein content, and distinctive nutty flavor, making it highly desirable for cheese making.

What are some celebrated sheep milk cheeses?

Pecorino Romano and Roquefort are some well-known examples of sheep milk cheeses enjoyed around the world.

How is buffalo milk used in cheese making?

Buffalo milk, known for its higher fat and protein content compared to cow milk, is a key ingredient in the production of mozzarella cheese. It imparts a stretchy and melt-in-your-mouth texture to the cheese.

Are there other animal milks used for cheese making?

Yes, in addition to cow, goat, sheep, and buffalo milk, there are also lesser-known animal milks such as camel milk and yak milk that yield unique and flavorsome cheeses.

What are the challenges involved in working with uncommon animal milks?

Uncommon animal milks like camel and yak milk present challenges in terms of availability, milk composition, and cheese production techniques. However, these milks are highly regarded for their premium nature and the distinct cheeses they yield.

How does milk selection impact cheese quality?

Milk selection plays a crucial role in determining the quality and characteristics of the cheese. Factors such as raw milk vs pasteurized milk and whole milk vs skim milk can influence the flavor, texture, and safety of the final product.

What is the role of rennet in milk coagulation for cheese making?

Rennet is a crucial ingredient in cheese making as it helps coagulate the milk proteins, forming the curds that will eventually become cheese. There are different types of rennet available, including animal-derived and microbial rennets.

What milk processing techniques are used in cheese making?

Milk processing techniques such as homogenization and pasteurization are commonly used in cheese making to ensure the quality and safety of the milk. Other techniques like ultrafiltration and thermal treatment can also be employed to modify the milk’s characteristics.

Why is milk choice important in cheese making?

Milk choice is important in cheese making as it determines the flavor, texture, and overall quality of the cheese. Different animal milks bring unique qualities to the cheese making process, resulting in a wide range of flavors and textures in the final product.

How does cheese making efficiency vary across different milk types?

Cheese making efficiency varies across different milk types due to variations in coagulation properties and curd firmness. Optimizing cheese production techniques for specific animal milks is crucial to achieve the desired flavor and texture.